This post is to show you my new workout program to keeping me in shape, or “how I mash,

After I order the grain, I need to pick it up myself (it is extremely cost-prohibitive to have it shipped across town to me). I then unload the bags of grain and haul them into the brewery, down the stairs, past my office, across the room to my grain mill. A typical batch might have 10 bags of grain at 50lb each, so 500lbs or a quarter ton!

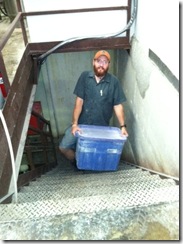

Then after I crush the grain, I put it in blue tubs (you know the Walmart kind) and haul the grain across the room, past my office, up the stairs to my brew house. Did I mention this is like a quarter ton?

When I’m ready to “dough-in” (brewery lingo for adding the crushed grain to the water, or vice versa) I manually dump the tubs into the mash tun. (so that’s why they call it a “tun/ton”!)

I probably forgot to mention that our brewery has no air movement and even though it is dry in Colorado, when you are boiling water in a closed room, you have perfect conditions for emulating the humidity of the Midwest. I try to combat my sweating by using a bandana headband. (not shown in pictures since I look too scary with my headband on.) I then swap it with a dry one after a 1/2 hour, rinse the drenched one and put it outside to dry. A half hour later it is dry and ready to swap (can’t do that in 95% humid Midwest climates)

This looks awful familiar. Photos showing me with my stainless steel mash paddle (extremely high tech since it is made out of stainless) and hovering over a 152 degF steaming tun of mash. This is the hottest of the all the jobs I do and keeps me in shape stirring over one ton of grain/water mixture manually.

After doing my normal brewing duties of vorloffing, sparging and lautering the wort into the kettle, I drain the remaining weak wort and then mash out. In a typical brewery this involves putting a large skid-sized crate under the mash tun and opening the man-way and you either have an automatic pusher to push out the grain or you use a big squeegy and pull/push it out the man-way. Notice my mash tun doesn’t have a man-way. This requires a special tool I call a “brewer’s shovel.” How many licks does it take to get to the center of a Toosie Pop?…..answer, the same number of scoops it takes to empty my mash tun with spent grains. I put them into large Rubbermaid garbage cans and haul them outside using another brewer’s tool—the hand-truck.

Where does all this spent grain go? I call a phone number and leave a message for some guy named John (I don’t know his last name) and he comes and picks up the grain for cattle feed.

So there you have it, mashing it old school. Isn’t there any other way? There really isn’t a way to justify a new or used mash tun, so I’m stuck with most of this process until my volume is like hexa-duple-tuples or something. But I did come up with the idea to move the grain mill to a shed outside, all I need is a 220V receptacle. So that will save me hauling a quarter ton of grain down and back up the steps again (not only is it time consuming, labor-intensive, and un-ergonomic, it is also quite unsafe) So that will be one of my next brewery improvements coming up.

No comments:

Post a Comment